बायॠसà¥à¤¬à¥à¤à¥ à¤à¤° 2à¤à¥ à¤à¤¥à¥à¤¨à¥à¤² पà¥à¤²à¤¾à¤à¤

बायॠसà¥à¤¬à¥à¤à¥ à¤à¤° 2à¤à¥ à¤à¤¥à¥à¤¨à¥à¤² पà¥à¤²à¤¾à¤à¤ Specification

- शोर का स्तर

- Low

- क्षमता

- 30-50 TPD

- मोटर पावर

- 125 kW

- फ़्रिक्वेंसी

- 50 Hz

- मटेरियल

- Stainless Steel

- वोल्टेज

- 440 V

- वज़न

- Up to 150 Ton

- स्वचालित ग्रेड

- Automatic

- कंट्रोल सिस्टम

- PLC Based

- साइज

- Customized

- रंग

- Silver/Grey

- प्रोसेसिंग टाइप

- Biofuel Production

- एप्लीकेशन

- Bio CBG & Second Generation Ethanol Production

- मोटाई

- 8-20 mm

- शीट की क्षमता

- Customizable

- Working Temperature

- Ambient to 65°C

- Safety Features

- Explosion-Proof Design, Emergency Shutoff System

- Utilities Required

- Water, Electricity, Compressed Air

- Operating Staff

- 3-6 Skilled Technicians

- Construction Type

- Modular Skid-Mounted

- Plant Lifespan

- 15-20 years

- Compliance Standard

- IS 16186:2014, CPCB Norms

- Output Products

- Bio-CBG, 2G Ethanol, Organic Fertilizer

- Automation Level

- Full Automation

- Gas Purification System

- Integrated Multi-stage

- Start-up Time

- 6-8 hours

- Installation Support

- On-Site & Remote Commissioning

- Feedstock Compatibility

- Agricultural Residue, Biomass

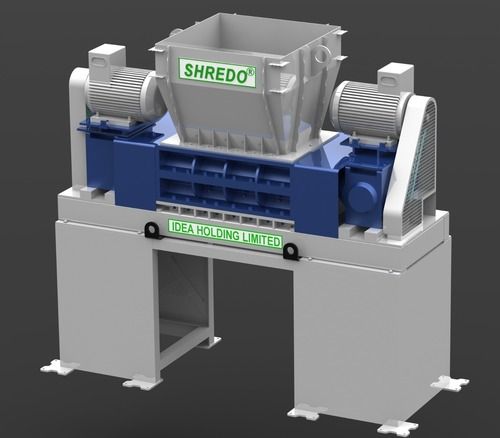

About बायॠसà¥à¤¬à¥à¤à¥ à¤à¤° 2à¤à¥ à¤à¤¥à¥à¤¨à¥à¤² पà¥à¤²à¤¾à¤à¤

Experience the elite Bio CBG & 2G Ethanol Plant-an inestimable solution for sustainable biofuel production. With phenomenal feedstock compatibility including agricultural residue and biomass, this modular, skid-mounted marvel delivers glorious output: Bio-CBG, 2G ethanol, and organic fertilizer. Shop now and seize our special rate to empower your operations with full automation, explosion-proof design, and integrated multi-stage gas purification. Compliance assured by IS 16186:2014 and CPCB norms. Engineered for longevity (15-20 years) and optimal performance at ambient to 65C with flexible capacity from 30-50 TPD. Available from India's trusted exporter, manufacturer, supplier, and service provider.

Application and Usage Scope of Bio CBG & 2G Ethanol Plant

Bio CBG & 2G Ethanol Plant is used for advanced biofuel production across diverse agricultural sites and industrial zones in India. The plant processes agricultural residue and biomass through a fully automated, PLC-based system. Application occurs onsite, utilizing minimal operating staff, and integrates directly into facility workflows. The method enables continuous output of Bio-CBG, ethanol, and organic fertilizer, streamlining sustainability for agricultural, energy, and manufacturing sectors.

Delivery, Payment, and Certifications of Bio CBG & 2G Ethanol Plant

All Bio CBG & 2G Ethanol Plants are securely packaged and delivered with reliable transport services, ensuring their pristine market value upon arrival. Typical delivery time depends on customization, with prompt fulfillment as per client needs. Payment terms are flexible to accommodate procurement requirements. Each unit is backed by essential certifications, including IS 16186:2014 and CPCB compliance, enhancing operational credibility and regulatory confidence for your business expansion.

Application and Usage Scope of Bio CBG & 2G Ethanol Plant

Bio CBG & 2G Ethanol Plant is used for advanced biofuel production across diverse agricultural sites and industrial zones in India. The plant processes agricultural residue and biomass through a fully automated, PLC-based system. Application occurs onsite, utilizing minimal operating staff, and integrates directly into facility workflows. The method enables continuous output of Bio-CBG, ethanol, and organic fertilizer, streamlining sustainability for agricultural, energy, and manufacturing sectors.

Delivery, Payment, and Certifications of Bio CBG & 2G Ethanol Plant

All Bio CBG & 2G Ethanol Plants are securely packaged and delivered with reliable transport services, ensuring their pristine market value upon arrival. Typical delivery time depends on customization, with prompt fulfillment as per client needs. Payment terms are flexible to accommodate procurement requirements. Each unit is backed by essential certifications, including IS 16186:2014 and CPCB compliance, enhancing operational credibility and regulatory confidence for your business expansion.

FAQ's of Bio CBG & 2G Ethanol Plant:

Q: How is the Bio CBG & 2G Ethanol Plant installed at the site?

A: Installation support for the Bio CBG & 2G Ethanol Plant includes both on-site and remote commissioning, ensuring seamless setup conducted by expert technicians.Q: What makes the Bio CBG & 2G Ethanol Plant compatible with various feedstocks?

A: The plant is engineered to process agricultural residue and biomass, providing flexibility in raw material selection to optimize product output and sustainability.Q: When can full automation and production commence after installation?

A: Full automation and production typically commence within 6-8 hours of plant start-up, following a thorough installation and system testing phase.Q: Where are the major application sites for this plant?

A: Major application sites include agricultural centers, biomass processing units, renewable energy hubs, and industrial facilities seeking advanced biofuel generation.Q: What is the process for producing Bio-CBG and 2G Ethanol in this plant?

A: The process involves automated feedstock handling, multi-stage gas purification, and precise biofuel conversion, all managed via a PLC-based control system.Q: How does the plant benefit operating facilities and the environment?

A: It enables efficient conversion of biomass into clean energy products, reduces agricultural waste, enhances market value, and supports sustainable industrial development.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें