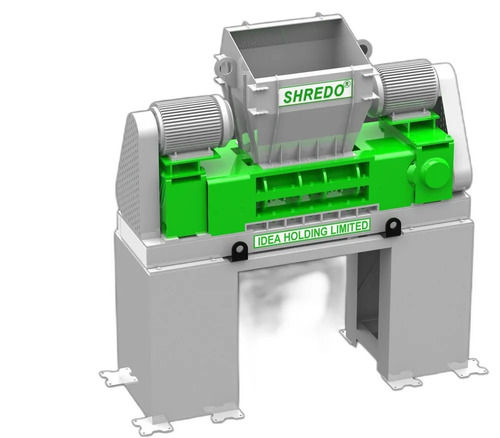

Biomass Shredders

Biomass Shredders Specification

- Application

- Biomass Processing, Agriculture Waste, Industry Waste Management

- Material

- Mild Steel

- Weight

- 1250 kg

- Voltage

- 415 V

- Capacity

- 1000-1500 kg/hr

- Processing Type

- Shredding/Cutting

- Sheet Capacity

- Multiple biomass sheets per cycle

- Automatic Grade

- Automatic

- Thickness

- 2-8 mm

- Frequency

- 50 Hz

- Noise Level

- 80-85 dB

- Color

- Green or Blue

- Control System

- PLC Control

- Size

- 2520 x 1430 x 1800 mm

- Motor Power

- 30 HP

- Mobility

- Stationary with Optionally Movable Base

- Number of Blades

- 20

- Discharge Type

- Belt Conveyor

- Feeding Type

- Conveyor or Hopper

- Safety Features

- Emergency Stop Button, Overload Protection

- Chamber Size

- 800 x 600 mm

- Shredding Blade Material

- Alloy Steel

- Operating Temperature Range

- -5°C to 45°C

- Power Consumption

- 22 kW

About Biomass Shredders

Having spent a decade on converting the patented design into a product and conducting filed trials, SHREDO has delivered one of the finest shredding machines to the customers that is said to be useful to shred various type farm residues such as Paddy Straw, Sugarcane Trash, Corn Stalk etc.To fulfill the demand of our customers for fine output size alongwith required capacity, we designed and delivered Primary & Secondary Shredding Systems. These systems are useful to feed the raw material into all types of boilers installed in power plants, ethanol plants, Bio-fuel plants and others. Further, we also provide the customized solutions to our customers by listening and analysing the complete requirements

Request

Callback

Additional Information:

- Production Capacity: 2-3TPH, 5TPH, 8-10TPH, 15TPH, 25TPH, 35TPH

- Delivery Time: 2-4 Months

- Packaging Details: Seaworthy Export Packing

Advanced Shredding Efficiency

Featuring 20 durable alloy steel blades and a spacious 800 x 600 mm shredding chamber, our shredder achieves high throughput for agricultural and industrial biomass. It is engineered for processing multiple sheets per cycle, streamlining waste management and biomass production processes.

Robust Safety and Control

Safety is paramount, with emergency stop buttons and overload protection as standard. PLC-based automatic control ensures operational reliability and precise shredding, while the belt conveyor enables seamless discharge and material handling.

Customizable and Flexible Design

Choose between stationary or optionally movable bases to fit specific facility layouts. With conveyor or hopper feeding options and a manageable noise level of 80-85 dB, this shredder easily integrates into various waste management environments in India and beyond.

FAQ's of Biomass Shredders:

Q: How does the PLC control system benefit the biomass shredder's operation?

A: The PLC (Programmable Logic Controller) system automates the shredding process, providing consistent performance, precise control over blade operations, and efficient material throughput. It also enables quick adjustments for changing input materials and enhances overall system reliability.Q: What safety features are included in the biomass shredder?

A: This shredder is equipped with essential safety features such as an emergency stop button, which halts operation immediately in case of anomalies, and overload protection, preventing potential equipment damage or hazards due to excessive load.Q: When is it best to use the optional movable base of the shredder?

A: The movable base is ideal when frequent relocation within a facility is required, such as shifting between different biomass processing stations or waste management zones. Otherwise, stationary installation is suited for fixed operations.Q: Where can this biomass shredder be integrated for optimal usage?

A: It is designed for seamless integration in biomass processing plants, agricultural waste handling sites, recycling centers, and industry waste management facilities throughout India or any region with similar infrastructure demands.Q: What is the process for feeding and discharging material in the shredder?

A: Material is introduced via conveyor or hopper, processed through 20 alloy steel shredding blades, and discharged efficiently using the integrated belt conveyor. This ensures continuous operation and easy collection of processed biomass.Q: How does the shredder's capacity benefit large-scale operations?

A: With a throughput of 1000-1500 kg/hr and the ability to process multiple sheets up to 8 mm thick, the machine is ideal for meeting substantial processing demands, reducing manual labor and maximizing productivity in large operations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Biomass Shredding Machine Category

Shredding Machine

Price 1520000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Shredded

Use : For Paper Industry

Cutter Type : Automatic

Voltage : 230 Volt (v)

Biomass Shreded

Price 1515000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Shredded

Use : For Industry

Cutter Type : Automatic

Biomass Shredder

Price 5500000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Shredder

Use : For Industry

Cutter Type : Automatic

Voltage : 230 Volt (v)

Municipal Solid Waste Shredding Machine

Price 2011000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Shredded

Use : For Industry

Cutter Type : Automatic

Voltage : 240 Volt (v)

Send Inquiry

Send Inquiry Send SMS

Send SMS